The JigSpace blog

Spatial for business: JigSpace launches on Apple Vision Pro

We’re excited to announce the launch of JigSpace on Apple Vision Pro, taking full advantage of its incredible capabilities, for training, sales and marketing.

Learn more

2023 Year in Review

A look back on some highlights from 2023 and revealing what’s in store for 2024.

Learn more

Jig Spark: A New Generative AI Tool for 3D Presentations

Utilizing the latest in AI technology, Spark extracts key information and context from both the CAD file and your website to generate a novel 3D presentation.

Learn more

SXSW Sydney Augmented Reality & Spatial Computing Recap

Explore the future of business with AR, 3D, and VR with our key insights from SXSW Sydney expo and our CEO Zac's keynote on spatial computing.

Learn more

Supercharge your Jig creation process with 5 new features exclusive to desktop

Discover the latest capabilities that make working with complex 3D models easier, plus creation tools to make your Jigs even more engaging.

Learn more

The top 6 augmented reality frameworks for businesses and creatives

Let's dive into the top six augmented reality frameworks for developers, businesses, and artists.

Learn more

JigSpace featured in the Apple Vision Pro announcement

Today, JigSpace was featured in the Apple Vision Pro announcement. All content created on the JigSpace platform will seamlessly work on the new device.

Learn more.png)

7 ideas for a successful trade show marketing strategy

Trade shows can be the key to a successful marketing strategy. Discover our top trade show marketing ideas and learn how to make your stand more engaging.

Learn more.png)

Blow your customers away with these top 5 product launch ideas

Spread the word and get your audience buzzing about an upcoming product or solution. Today, we’ll be exploring five product launch ideas for manufacturers.

Learn more.png)

B2B sales and marketing assets that convert in 2023

Discover the best marketing materials and sales collateral of 2023, and learn how to make them even more effective with 3D and AR technology.

Learn more

5 key learnings from early adopters of 3D & AR technology

On February 2, 2023, JigSpace and the VR/AR Association brought together leaders from across the globe to explore how augmented reality (AR) can transform the customer experience.

Learn more

The highlights of 2022 ... and what's ahead for the new year

2022 was a year of intense growth and development for JigSpace. Today, we’re reflecting on some of the highlights, and revealing what’s in store for 2023.

Learn more

Seamless AR experiences with Apple App Clips

Apple App Clip technology is fast, efficient, and smooth, making it one of the easiest ways to view JigSpace content, and it's now available for all our users.

Learn more

9 exciting new JigSpace updates

Our latest updates are designed to optimize your experience with JigSpace while making the workshop more user-friendly for new and experienced creators alike.

Learn more.png)

How immersive learning technologies are transforming employee training

Is immersive training really the way of the future? Explore the benefits of immersive learning technology and how it can transform employee training forever.

Learn more

How to utilize AR learning materials in remote training

Discover practical ways of using AR learning to support information retention, boost engagement, and improve the way you train your employees remotely.

Learn more

The future of digital marketing

Explore the future of digital marketing and the opportunities awaiting innovative businesses who can take advantage of new trends, technology, and platforms.

Learn more

The benefits of augmented reality in marketing

There are many benefits to using augmented reality in your marketing strategy. Find out how you can leverage the power of AR to get your message across.

Learn more

JigSpace x Alfa Romeo F1® Team ORLEN | Launching a race car into the metaverse

How Alfa Romeo F1® Team ORLEN and JigSpace teamed up to launch the 2022 race car, C42 race car into the metaverse for the very first time.

Learn more

7 showstopping trade show examples to inspire your next appearance

Explore our top trade show examples. You can use these as inspiration for your own trade show marketing materials to really wow your audience.

Learn more

2D to 3D digital transformation - Why all communication should be recorded in 3D

We chatted with the experts in digital engineering at The Design Technology Company (DTCo.) to learn why ensuring an entire production process from conception to build should be recorded as 3D information.

Learn more

Digital prototyping VS traditional methods - Where does the value lie?

Clever JigSpace customers in the engineering & manufacturing industries like DTCo are finding new ways to extract maximum value from their 3D CAD data.

Learn more

New: teams, 1:1 true scale, image upload, and masterclass tutorials.

This update is designed to improve the quality of life for creators; speeding up the time it takes to make quick, simple, 3D presentations to share within teams.

Learn more

Alfa Romeo F1 Team ORLEN names JigSpace as their official metaverse partner!

We are thrilled to FINALLY let the cat out of the bag on quite possibly one of the most exciting partnerships that we could kick off 2022 with! We are the official partners of Alfa Romeo F1 Team Orlen!

Learn more

What's in store for 2022?

2022 is going to be HUGE. Here lies some exciting upcoming product features and news!

Learn more

JigSpace WINS at Snap AR Lens Fest!

The judges at Snapchat have selected JigSpace as a winner! To win Best in Technical Skill at the inaugural Lens Fest Awards and be named among the best of the best creators in AR is humbling and exciting.

Learn more

New: Bring CAD files to life, faster and easier than ever before.

This release focuses on improvements to the way JigSpace manages your CAD files, plus some exciting new effects you can apply to your Jigs!

Learn more

Ever wondered how a Ghostbusters Proton Pack works?

With the Halloween spooky season just around the corner, we couldn't help but wonder... Is there a greater piece of tech that exists, in the world of cinema, than the Ghostbusters proton pack?

Learn more

How To: Sharing "Team Jigs".

We've made it faster to share team-wide content for Jig Pro users. This feature is now right inside the JigSpace app. Let us walk you though how this is done...

Learn more

New: Sharing Jigs is now even easier

Sharing is caring, and one of the most requested features we receive is the ability to share Jig content with anyone! We’ve redesigned the way you share Jigs with your team and customers, read more...

Learn more

Is sharing knowledge and collaboration easier in 3D?

We certainly think so. Photographs, line drawings and schematics are certainly useful, but they only give a 2 dimensional understanding of how something really works.

Learn more

New: Better viewing and sharing experiences

JigSpace release 3.4.0 is about making more delightful, interactive viewing experiences. Some most requested updates are finally here that truly add to the magic of sharing knowledge in 3D.

Learn more

New: Add audio, video, and images to 3D presentations

You can now add video, audio and images to your 3D augmented reality presentations in JigSpace. We're excited to see what immersive experiences you create!

Learn more%252520Zac%252520Duff%252520(R)%2525201280x720.png)

Announcing our AUD$6 million Series A funding

At the heart of Jig there is a simple truth - we learn better in 3D, because that's how we experience the world.

Learn more

Oh Snap! JigSpace partners with Snap to scan the world

JigSpace will be one of the first Lens partners utilizing powerful scan technology to unlock augmented reality instructions and information from within the Snapchat app.

Learn more

Major Update: Explore, create, share in one JigSpace app 🚀

Hi there! We’ve got some very exciting news…

Learn more

LiDAR and SolidWorks - more ways to bring content into your Jigs

LiDAR is making huge improvements to JigSpace and you can now easily upload SolidWorks engineering files to your 3D presentations.

Learn more

JigSpace LiDAR and 5G innovations featured at Apple iPhone 12 Launch

Today, Jig Pro was featured in the Apple keynote event.

Learn more

Accelerating ventilator knowledge to help address global demand

When Medtronic plc openly shared their Puritan Bennett™ 560 (PB560) ventilator plans back in April to help boost global ventilator production.

Learn more

Remote augmented reality presentations are now available

So you have almost perfected your 3D presentation (we call them 'Jigs') and you need your international team's feedback?

Learn more

AR presentations and product demos with Hino Trucks

It is easy to fall into the trap of under-selling when you manufacture products that are big, complex, and expensive.

Learn more

Why we created Jig Pro

At JigSpace, our mission is to let anyone share their knowledge with spatial computing.

Learn more

Augmented reality product training with Swoop Aero

How do you train remote communities to operate the latest drone technology, who have never seen an aeroplane up close or flown in one?

Learn more

Meet the co-founders of JigSpace: Zac Duff and Numa Bertron

JigSpace is spatial presentations made easy and one of the world's top augmented reality apps.

Learn moreJigSpace tutorials

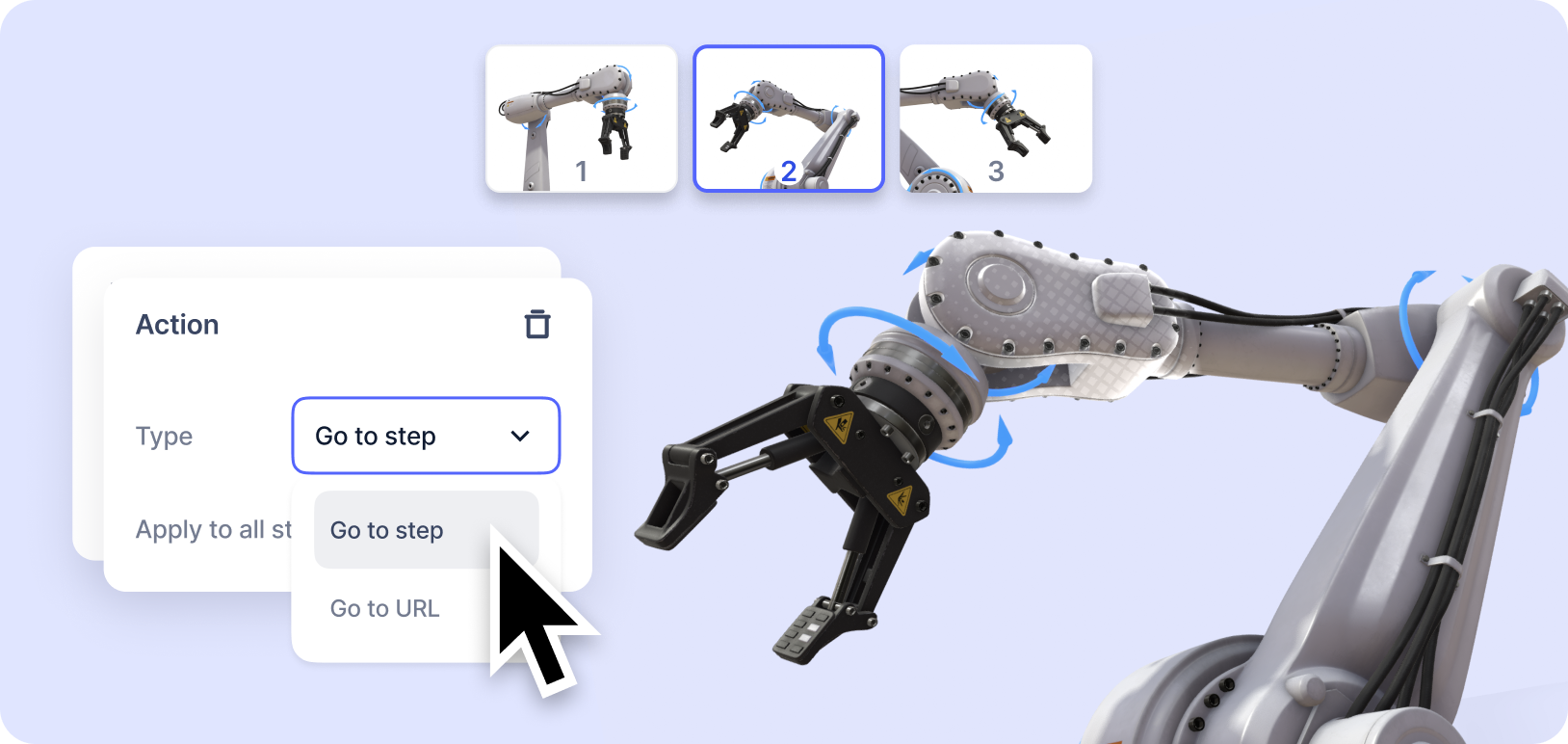

Interactive navigation webinar replay

Video replay of live workshop showing how to elevate 3D training and presentations with interactive navigation

Use actions to enhance your Jigs

Make your Jigs more engaging by letting viewers interact with your product.

JigSpace 3D model preparation

Prepare your 3D models for smoother, faster rendering in JigSpace.

Feature your product in a 3D demo

Learn how to make exciting product demonstrations using JigSpace.